HEFT GROUP

HEFT was established in September 2010, which is a manufacturer specialized in STAINLESS STEEL with PVD COATING, serving dozens of luxury leathergoods brands. It is a strong team of technically innovative, rigorous and orderly engineers, and an efficient management team for organizational operations.

What can we provide?

We can provide designers with product design elements in a timely manner, quickly turn your designs into works, deliver your production on time, and ensure the quality of your products. The entire industry chain is an independent and controllable manufacturer, completely solving the hidden dangers of dispersed and uncontrollable supply chain!

What can we do ?

Our production and manufacturing capabilities include MIM, STAMPING, CNC machining, 3D metal printing, Laser welding, Chemial etching etc...

We have surface treatment technology: Polishing, Sandblasting, Brushing, Vibration, PVD etc...

Our product range is complete, including functional locks, metal chains, rings, snap hooks, buckles, pull tags, logo letters, frames, rivets, eyelets, magnetic buttons, jewelry necklaces, bracelets, earrings, fingerrings etc...

Prototype leadtime: 7-10 working days

Production leadtime: 3-4 weeks

Mold leadtime: 7-10 working days

Number of empolyees: 450+

Factory area: 18000+SQM

Monthly capacity: 3mil pcs

SUSTAINABILITY

-OUR SOLOGAN: LOW CARBON, LOW WATER, LOW ENERGY

-SOLAR ENERGY SUPPLY PARTIALLY

-INHOUSE RECYCLING

-INHOUSE DISPOSAL SYSTEM OF WASTE WATER

CERTIFICATION

-ISO9001:2005 Quality Certification System

-SA-8000 Social Responsibility Certification

-ISO 14001 Environmental Certification

-LUXURY GROUP AUDIT CERTIFICATION

QUALITY ASSURANCE SYSTEM

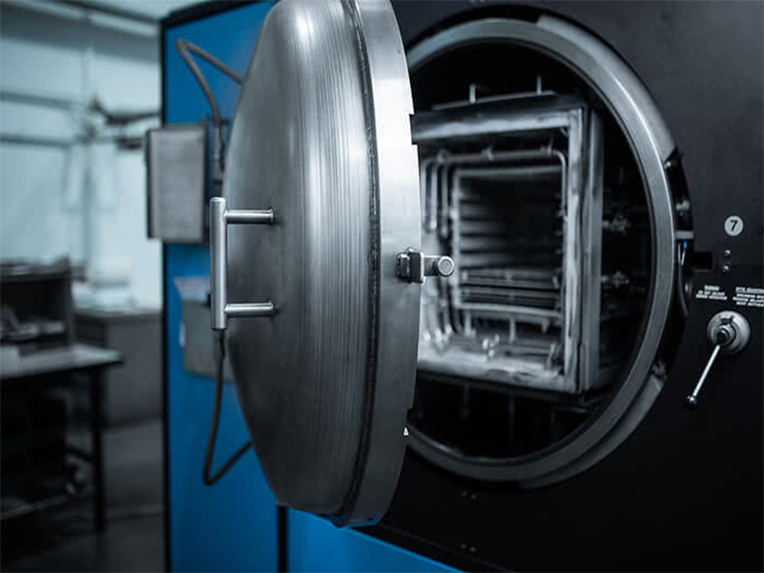

Our inhouse laboratory is able to conduct below test:

Chemical tests: Salt spray test (NSS), Artificial sweat test, Damp/heat test, Thermal shock test, Anti-abrasion test. etc..

Physical tests: X-ray thickness test, Traction test, Torsion test, Cage drop test, Life cycling test, Cross-cut tape test, Free-drop shock test. etc..